SF-HP Heat-Pulse Sap Flow Sensors

Just as with TDP sap flow flow sensors, heat-pulse sap flow sensors also work on a temperature-based measuring principle. A major difference, however, is that HP sap flow sensors do not require continuous heating, but only a short heat pulse of a few seconds is applied. Depending on the measurement method used, the direction-dependent propagation as well temporal dynamics of the heat pulse is then recorded and based on that flow speed and flow direction of the xylem sap flow is determined. Several measuring points along the measuring needles enable the radial sap flow profile to be recorded.

Compared to the TDP method, energy consumption of HP sap flow sensors is drastically reduced, enabling the use of this type of sap flow sensors also in battery operated low-power applications such as in the IoT field (see IoP).

We currently offer the following different versions:

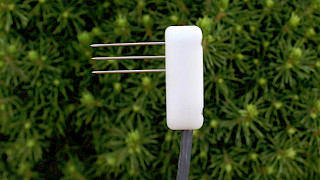

- SF-HP-N3D2, with three 30 mm long sensor needles. The upper and lower measuring needles are each 6 mm away from the middle heating needle and each have two measuring points at 10 mm and 20 mm from sensor head.

- SF-HP-N3D3, with three 35 mm long sensor needles. The upper and lower measuring needles are each 6 mm away from the middle heating needle and each have three measuring points at equal distances from each other at 5 mm, 17.5 mm and 30 mm from the sensor head.

Customized needle lengths and measuring point positions (e.g. for small plant diameters) are possible on request!

Advantages of HP-Sap Flow Sensors

- Significantly lower energy consumption compared to juice flow sensors with constant heating (e.g. TDP sensors such as SF-G or SF-L).

- Equipped with several measuring points in each measurement needle, the radial sap flow depth profile can be recorded.

- The three-wire sensor design enables the direction of flow to be determined, i.e. also the detection of reverse flux as well as the use of the "Dual Method Approach" which combines the advantages of HRM and Tmax measuring methods and thus allows precise measurements in the entire range from slow to fast sap flow velocities.

- The underlying measuring principle itself is less susceptible to natural temperature gradients than compared to that of TDP sensors.

- Analogue output signal stronger (in the range of volts) than with TDP sensors (signals in the range of 1 millivolt), i.e. the relevant requirements for the data logger are significantly lower.

- Sensors are very robust.

Limits of HP-Sap Flow Sensors

- Measurements cannot be taken continuously, i.e. the maximum time resolution is in the range of 10 to 15 minutes.

- Depending on the measurement method used (e.g. HRM, Tmax or DMA), the control of the sensor and the data processing of the sensor data generated during the measurement is relatively complex. The requirements on the data logger are therefore high in terms of measuring frequency, flexible programmability and data processing (Campbell Scientific Logger recommended, or our soon available multi-interface for integration via e.g. RS485).

- Especially in the case of the Tmax and DMA methods, the data logger requires a measurement resolution of 0.01°C and a measurement frequency of at least 120 Hz during the measurement.

- Depending on the sensor model, 4 (SF-HP-N3-D2) or 6 (SF-HP-N3-D3) measurement channels are required.

Models

| Models | Suitable for stem diameter |

|---|---|

| SF-HP-N3D3 | > 35 mm |

| SF-HP-N3D2 | > 30 mm |

| Customized SF-HP Sensor on request | < 30mm |

Technical Data

| Sensor model name | Heat pulse Sap-Flow Sensor SF-HP-N3D3 | Heat pulse Sap-Flow Sensor SF-HP-N3D2 |

| Scope of application | For measuring the sap flow in woody plants | |

Suitable for diameter | > 35 mm | > 30 mm (Sensors for smaller diameters on request) |

Number and alignment of the sensor needles | 3 needles arranged in a line one above the other (1. upper measuring needle - 2. heating needle - 3. lower measuring needle), distances between the heating needle and the measuring needles are 6 mm each | |

Measurement depths | Measuring points at 3 depths at a distance of 5, 17.5 and 30 mm from the sensor head | Measuring points at 2 depths at a distance of 10 and 20 mm from the sensor head |

Sensor dimensions | Sensor head (HxWxD): 45 mm x 20 mm x 16 mm. Needle Diameter: 1.27 mm; Needle Length: 35 mm | Sensor head (HxWxD): 45 mm x 20 mm x 16 mm. Needle Diameter: 1.27 mm; Needle Length: 30 mm |

Output signal | Analog, voltage 0 to supply voltage Vex (recommended: 1 < Vex < 3.3 VDC) | |

Technical requirements for the data logger used | 6x single ended measurement channels, noise-free resolution at least 0.01°C, i.e. 14 bits in the range from 0 to supply voltage Vex. To use the Tmax, or the Dual Approach (HRM + Tmax) measurement method, the logger requires a measurement frequency of > 10 Hz (i.e. all 6 sensor channels in < 0.6 seconds) Recommended: ratiometric half bridge measurement, with Vex = Vref of the logger. Data loggers from Campbell Scientific are ideally suited. | 4x single ended measurement channels, noise-free resolution at least 0.01°C, i.e. 14 bits in the range from 0 to supply voltage Vex. To use the Tmax, or the Dual Approach (HRM + Tmax) measurement method, the logger requires a measurement frequency of > 6.7 Hz (i.e. all 4 sensor channels in < 0.6 seconds) Recommended: ratiometric half bridge measurement, with Vex = Vref of the logger. Data loggers from Campbell Scientific are ideally suited. |

Sensor power supply | SF-HP sensors require two different power supplies: 1.: Switched excitation voltage (Vex) for the temperature measurement, recommended: 1 < Vex < 3.3 VDC. At best, ratiometric measurement with Vex = Vref of the logger 2.: Precisely timed heating current, 8 seconds approx. 300 mA, at 11 - 13 VDC. Energy consumption per measurement 0.67 mAh at 12V, i.e. 8 mWh. The usable capacity of a 10 Ah 12V battery is sufficient for around 10,000 measurements. | |

Sensor cable length | 5 m, extendable to max. 25 m | |

| Material | Epoxy and Delrin head, stainless steel needles | |

Accessories & Compatible Products

Datenlogger and other accessories:

From small and compact to an extensive measuring network, Ecomatik offers complete system solutions for sensor data acquisition in any desired size:

- Maxi-Systems (e.g. Campbell data logger station)

In addition to a suitable data logger, the operation of heat-pulse sap flow sensors requires a heating control element which is controlled by the logger and applies the electric current pulse for the heating needles of the connected heat-pulse sap flow sensors. Additional tools and materials are required for installation (drill guide, special drill bit for accurate installation and d best needle fit, mini hex chuck to hold drill bit securely while drilling, reflective insulation for temperature regulation). All required accessories, tools and material can also be obtained from Ecomatik. If you order a complete Heat-Pulse juice flow system, all the necessary components are already installed, wired and preconfigured in a logger box.

Note

Depending on the measurement method used, the operation of heat-pulse sap flow sensors requires a more or less complex, temporally precise and high-frequency (at least every 500 msec) readout of the 6 (SF-HP-N3D3) or 4 (SF-HP-N3D2) sensor outputs as well as a precisely timed application of the heat pulse. The requirement for the analog measurement is a noise-free resolution of at least 0.01°C. All logger systems from Campbell Scientific are suitable for operating our heat-pulse sap flow sensors.

In case of doubts about the compatibility of your existing data logger, please do not hesitate to contact us.

Contact

You need a quotation, have questions about a product, or need extensive technical advice in the context of your project planning. Starting with an initial determination of your needs, through the detailed planning of the required measurement equipment and data transmission technology, up to professional implementation on site, we are at your disposal at any time with advice and action.

General information on order processing

Thank you for your interest in our products and services! Here you will find important information about the ordering process:

To our international customers: Please note, we ship worldwide! If we do not currently have a listed distributor in your country (a list can be found here) , please feel free to contact us directly.

Assessment of your needs

With your consideration and input, we determine which of our products best meet your needs. We are also happy to design fully-integrated measuring stations (plant, climate, soil sensors), including an independent power supply and mobile data transmission, depending on your requirements.

Do you require our assistance before placing an order?

We are happy to help! So that we can provide you with correct and helpful advice, please fill out the online form below with your contact details and other information about your application and send it our way. We will then immediately review your details and contact you.

Are you already familiar with our products and know exactly what you need?

Perfect, then just write us an email! In your order, please state the diameter of your measuring objects in addition to the required cable lengths.

Your contact details and Assessment of your needs

Like so many things, everything started with an idea ...

In the case of the plant scientist and founder of ECOMATIK, Dr. Liu, it was the idea that modern measurement technology should enable crucial plant physiological parameters to be measured directly, precisely and with high temporal resolution on the plant itself. It was obvious to him that there is an information potential of immense value in the detailed understanding of immediate reactions of plants to their environment...